When I first started shooting bulls-eye competitions, I was next to a shooter using a 1911 with a six-inch barrel. In my naiveté, I asked him what was the benefit of his 6” 1911 compared to my standard 5” 1911? He humorously replied… “I’m an inch closer to the target than you are!” There is a lot more to accuracy and precision than barrel length alone.

Precision vs. Accuracy

Firearm precision is simply a matter of mechanical repeatability. By this, I mean the mechanical components of the firearm must interact in a controlled and consistent manner to launch the projectile exactly the same way. If these mechanical components do not interact in a consistent manner, the net result may negate all other factors, thus sending projectiles outside of the desired area within the target. For example, a shooter may have selected the correct ammunition matched to the weapon and exercised a highly refined shooting technique, only to find the point of impact on target is inconsistent. No combination of applied shooting principles can overcome a lack of mechanical precision.

Firearm Construction

Tolerance is a key contributor to firearm precision. It is defined as the dimensional relationship between moving mechanical parts, or how well the different firearm components fit together. While it is obvious the moving parts within a firearm require enough clearance to perform their functions, excessive gaps can cause inconsistent alignment and reduce precision. Mass produced firearms tend to cost less due to the manufacturer’s ability to fabricate thousands of interchangeable parts in a single run to construct their firearms. In general, these firearms tend to be inherently “more” functional but “less” precise due to the lower tolerance engineered into each component. Note that the terms “more” and “less” are generalizations and vary among manufacturers. Conversely, firearms built with high tolerances and hand-fit components seem “tighter” and result in a lower manufacturing volume, higher cost and greater maintenance requirements to ensure reliable function.

Anyone who has had the opportunity to shoot an old 1911 may have noticed they “rattle” when you shake them… yet they are still VERY accurate. The rattling sound is typically the physical contact between the slide and the frame where there is a low tolerance due to high volume production and the need for consistent function. However, this unique pistol remains accurate due to a higher tolerance where it is most needed. The area where the rear of the barrel locks into the slide and the front of the barrel is secured by the barrel bushing.

Each shooter must decide their own threshold of precision, cost, and reliable function in their firearm selection. Below, I will describe a few other key characteristics of firearm construction as they relate to both precision and function.

Headspace: As the cartridge is stripped from the magazine or manually inserted and the firearm chambers and locks, headspace is defined as any measurable gap between the cartridge base and the bolt face, breech or receiver. Excessive headspace allows the cartridge to “move” in relation to the bolt, breech face or receiver and produce inconsistent ignition or allow expanding gasses to escape. This influences the travel of the projectile into the bore. Extractor quality, shape, construction, and tension play a key role in reducing headspace. Heavily used guns can also experience erosion on the face of the bolt, breech or receiver. In any case, improper headspace degrades both precision and function.

Barrel length: Each shooter must select a firearm with a barrel length that suits their individual needs. Shorter barrels benefit those who desire lighter and more concealable firearms. Longer barrels tend to benefit shooters who don’t mind the added weight and are interested in greater precision and accuracy. Longer barrels inherently present a longer sight radius, which improves accuracy. Concurrently, increased precision is also produced by the greater duration from which the barrel influences the travel of the projectile before it is released into the atmosphere. Longer barrels also provide a greater initial velocity due to the duration of the powder burn, gas expansion, and pressure build-up.

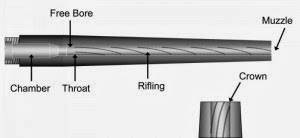

Barrel Effects: While shooting a firearm, the most noticeable effects are impulse (the bang) and the subsequent recoil in conjunction with the movement of the slide or bolt. However, few shooters realize there is a tremendous amount of activity within the barrel itself. The rapid gas expansion that creates pressure to propel a projectile down the bore causes the barrel to expand. Concurrently, the rifling that forces the projectile to spin as it proceeds down the bore also creates a torque in the opposite direction, causing the barrel to “twist” in the opposite direction of the rifling.

Meanwhile, the impulse and rapid gas expansion that sends the projectile forward also causes the barrel to vibrate and literally whip. Picture yourself holding the end of a taught rope, quickly moving the end in your hand, and watching the wave move down the rope. With all these forces acting on the barrel as the projectile moves forward, mechanical precision can only be attained if the projectile exits the moving barrel at the exact same time in its movement. The amount of barrel movement is affected by the quality of the barrel construction material, barrel thickness and the points of contact with the barrel (in rifles, this is considered bedding or free floating to ensure there is limited contact with the stock). In general, lighter and thinner barrels are more affected by expansion, twist, vibration and whip. Conversely, heavier and thicker barrels are less affected and enhance precision.

Stay safe and shoot straight!

First Published at Aegis Academy

About Author

- Howard Hall

Range Master

No comments:

Post a Comment