Unfortunately, most of us have experienced this at one time or another. We’ve inserted a loaded magazine, released the slide, chambered a round, disengaged the safety, aligned the sights in the center of the target, slowly exhaled while pressing the trigger, and as we felt the sear release the hammer or striker we heard a “Click” instead of a “BANG!”

On the range, it may be an annoying inconvenience to wait 30 seconds with the pistol pointed in a safe direction before “tapping” the base of the magazine, “racking” the slide to eject a possibly bad round and chamber what we hope to be a “good” one, “assessing” the target area, and deciding whether or not to fire again. In a personal defense, law enforcement, or military scenario, however, the most deafening sound has been described as the “Click” instead of the “BANG” required to stop the threat.

In the previous article, we covered malfunctions that occur during the first three steps in the cycle of operation: Feeding, Chambering, and Locking. In this article, we will focus solely on malfunctions that occur in the “Firing” stage.

Assuming the pistol has successfully fed, chambered, and locked, there are only two types of malfunctions that would prevent the pistol from successfully firing. These can be isolated to either the ammunition or the pistol’s ignition system. First, let’s cover ammunition failures.

Ammunition Failure

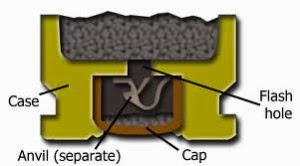

If you recall from Internal Ballistics – Part III, we described pistol cartridge components: primer, case, propellant, and projectile. In order to focus this part of the discussion to ammunition, we need to assume that the pistol is mechanically functioning as intended and the cartridge is correctly chambered. Under these conditions, the ammunition failure must lie in the propellant or the primer.

Propellant – If there is an insufficient quantity of propellant in the cartridge case, the primer/propellant ignition chain will not produce enough pressure to propel the projectile all of the way through the barrel. This is known as a “squib,” and the shooter should notice an audible “pop” instead of a “BANG” along with an under-powered recoil.

Propellant – If there is an insufficient quantity of propellant in the cartridge case, the primer/propellant ignition chain will not produce enough pressure to propel the projectile all of the way through the barrel. This is known as a “squib,” and the shooter should notice an audible “pop” instead of a “BANG” along with an under-powered recoil.

Again, in this section we’ve assumed that the cartridge is properly aligned on the breech face and the firing pin or striker has moved forward with enough force to ignite a normally functioning primer. However, there are some instances where the primer won’t function. First, the primer’s cap can be too thick or internal components can be incorrectly manufactured. Next, the primer can be set too low into the cartridge case and “out of range” of a normally functioning firing pin or striker.

Lastly, an error in the cartridge manufacturing process can misalign, damage, or invert the primer. While all of the former defects would be difficult to ascertain, the latter can be diagnosed by visual inspection. (right inset photo)

Lastly, an error in the cartridge manufacturing process can misalign, damage, or invert the primer. While all of the former defects would be difficult to ascertain, the latter can be diagnosed by visual inspection. (right inset photo)Firearm Mechanical Failure

Turning things around, in this section we will assume that we have chambered a properly constructed cartridge, but a mechanical failure in the firearm itself is the cause of the malfunction. This leaves us to consider the following possibilities: (1) Something is preventing the firing pin or striker from moving forward with enough force to properly ignite the primer; (2) the firing pin is damaged; or (3) the firing pin or striker is moving forward properly, but the cartridge is misaligned Read More>>

About Author

Howard has served for nearly 20 years in the Marine Corps. He has served as a Platoon Commander, Company Commander, Battalion Executive Officer, Regimental Operations Officer, and Battalion Commander. He has multiple combat tours to include serving as a military transition team member in Fallujah. He is an NRA Certified handgun instructor and holds numerous Marine Corps training credentials.

An active competitor in action pistol (United States Practical Shooting Association), long range rifle (NRA F-Class), and shotgun (Amateur Trapshooting Association, National Skeet Shooting Association), howard has earned numerous accolades and medaled during DoD competitions with the 1911 platform in bulls-eye shooting.