Welcome back and thank you for returning to read the final installment in the Diagnosing Pistol Malfunctions series. To cover the wide range of topics in this series, I have broken the 8 elements of the cycle of operation into the three commonly accepted types of pistol malfunction. Part 1, Failure to Feed, covered the first three elements: feeding, chambering, and locking. Part 2, Failure to Fire, covered the fourth and fifth elements: firing and unlocking. In Part 3, Failure to Eject, we will discuss the remaining three elements within the cycle of operation: extracting, ejecting, and cocking. Within this category of stoppages, I will analyze the three main causes: (1) failure to extract; (2) double feed; and (3) stove pipe.

Welcome back and thank you for returning to read the final installment in the Diagnosing Pistol Malfunctions series. To cover the wide range of topics in this series, I have broken the 8 elements of the cycle of operation into the three commonly accepted types of pistol malfunction. Part 1, Failure to Feed, covered the first three elements: feeding, chambering, and locking. Part 2, Failure to Fire, covered the fourth and fifth elements: firing and unlocking. In Part 3, Failure to Eject, we will discuss the remaining three elements within the cycle of operation: extracting, ejecting, and cocking. Within this category of stoppages, I will analyze the three main causes: (1) failure to extract; (2) double feed; and (3) stove pipe.As we begin this discussion, I believe it is important to once again emphasize the preeminent role of the extractor and highlight its counterpoise with the ejector. In both Part 1 and Part 2 of the series, I described the extractor’s role in properly guiding a cartridge case along the breech face during the feeding cycle as well as its role in firmly holding the cartridge in place centering the primer in front of the firing pin hole.

In Part 3, we will discuss the extractor’s profound role as the extractor claw “grips” the cartridge rim as the firearm unlocks and the rearward movement of the slide “extracts” the spent cartridge case from the chamber. As the slide continues its full rearward movement, the extractor maintains proper tension on the cartridge case holding it in position against the breech face until the continued rearward motion thrusts the base of the cartridge case against the ejector. Working in unison, the extractor continues to pull as the ejector pushes the spent cartridge case through the ejection port and away from the pistol… just in time for the slide to begin its forward motion which will feed the next round.

In Part 3, we will discuss the extractor’s profound role as the extractor claw “grips” the cartridge rim as the firearm unlocks and the rearward movement of the slide “extracts” the spent cartridge case from the chamber. As the slide continues its full rearward movement, the extractor maintains proper tension on the cartridge case holding it in position against the breech face until the continued rearward motion thrusts the base of the cartridge case against the ejector. Working in unison, the extractor continues to pull as the ejector pushes the spent cartridge case through the ejection port and away from the pistol… just in time for the slide to begin its forward motion which will feed the next round.

Failure to Extract

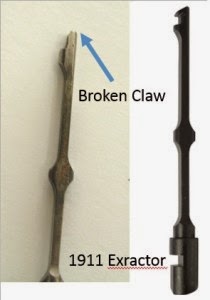

A failure to extract occurs when the cycle of operation is interrupted by a cartridge case that becomes stuck in the chamber. Even with a dirty chamber or a corroded cartridge case, the extractor tension combined with rapid slide movement create enough force to pull the case from the chamber. Therefore, the most likely cause of a failure to extract is either a broken extractor or one with improper tension. A brief visual inspection of the extractor claw can indicate excessive wear, damage, or a clean break. The photo to the right compares two 1911 extractors. One clearly has a broken claw. The only remedy to this problem is a full replacement. The good news is that most manufacturers produce quality extractors that are very affordable. They can range from $15.00 to $45.00 depending on the "name brand" you go with. Wilson Combat 1911 extractors are in the mid-$30.00 range and Glock extractors are just under $20.00. Since these are such an important item, it is a good idea to keep a spare extractor or two in your range bag.

A brief visual inspection of the extractor claw can indicate excessive wear, damage, or a clean break. The photo to the right compares two 1911 extractors. One clearly has a broken claw. The only remedy to this problem is a full replacement. The good news is that most manufacturers produce quality extractors that are very affordable. They can range from $15.00 to $45.00 depending on the "name brand" you go with. Wilson Combat 1911 extractors are in the mid-$30.00 range and Glock extractors are just under $20.00. Since these are such an important item, it is a good idea to keep a spare extractor or two in your range bag.When designed internal to the slide, such as most 1911s, the extractor is typically a solid piece of steel with a claw protruding into the breech. A "bow" in this solid piece of steel provides tension to the cartridge case. As such, the internal extractor itself can be considered a spring. The degree of the "bow" determines how much or how little tension is applied to the cartridge case.

When designed external to the slide, such as Glocks and Sigs, the extractor is one or more pieces of metal also with a claw protruding into the breech. External extractors rely on leverage and a spring to provide proper tension.

Whether internal or external, too much extractor tension may cause a failure to feed, but too little extractor tension could cause both a failure to feed and a failure to extract. In the case of a failure to extract, there just isn’t enough tension at the extractor claw to pull the case from the chamber. A visual inspection may not allow you to ascertain proper extractor tension.

If you recall from previous discussions, proper extractor tension can be determined by removing the slide from your pistol and pushing a loaded cartridge case against the breech face with the case rim under the extractor claw. Once in place, shake the slide in your hand. The cartridge should remain in place. If it falls free, there may be insufficient extractor tension.

If you determine you have insufficient extractor tension, I recommend conducting a detailed disassembly and cleaning of your slide. Built-up dirt may be limiting the movement of your extractor and its parts. If cleaning the extractor, channel, and springs does not correct the problem, then you may need to modify or change some parts. If you have a one-piece internal extractor, you can "bend" it a little further inward to

increase the "bow," and thus the tension. If you have an external extractor, you may need to replace the springs.

Double Feed

A double feed is one of the most difficult stoppages to clear… especially under pressure. "Tap… Rack… Assess" will either fail to correct the problem or create yet another double feed. It requires you to lock the slide to the rear, remove the magazine, “rack” the slide repeatedly to remove any cartridges, reinsert the magazine, and then chamber another round.But what causes it? Read More »

About Author: Howard Hall (Range Master)

Howard has served for nearly 20 years in the Marine Corps. He has served as a Platoon Commander, Company Commander, Battalion Executive Officer, Regimental Operations Officer, and Battalion Commander. He has multiple combat tours to include serving as a military transition team member in Fallujah. He is an NRA Certified handgun instructor and holds numerous Marine Corps training credentials.An active competitor in action pistol (United States Practical Shooting Association), long range rifle (NRA F-Class), and shotgun (Amateur Trapshooting Association, National Skeet Shooting Association), howard has earned numerous accolades and medaled during DoD competitions with the 1911 platform in bulls-eye shooting.